🏭 Effluent Treatment Plant (ETP) Solutions: Industrial Wastewater Treatment Systems 💧

🌍 Expert ETP Systems for Complete Industrial Compliance

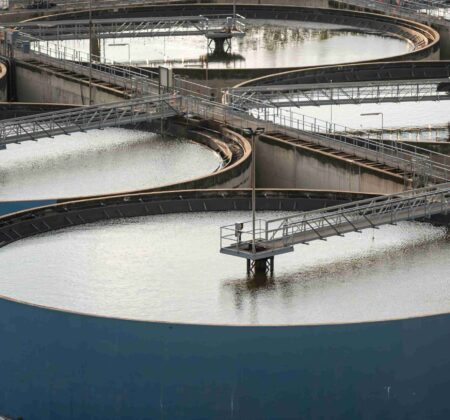

We provide cutting-edge Effluent Treatment Plant (ETP) solutions specifically designed to treat complex industrial wastewater efficiently. Our advanced ETP systems ensure your facility achieves strict environmental compliance while enabling sustainable water recycling and reuse practices. 🌱✨

From compact ETPs for small-scale operations to large industrial effluent treatment plants handling millions of liters daily, our proven ETP technology delivers reliable, cost-effective performance. Our effluent treatment plant designs incorporate physico-chemical treatment, biological processes, and advanced filtration—customized for your industry's unique discharge characteristics. 💪🔧

Whether you need textile ETP, pharmaceutical effluent treatment plant, chemical ETP, or food processing wastewater solutions, our ETP experts engineer systems meeting CPCB/SPCB norms. Experience superior effluent treatment plant performance with automated controls, remote monitoring, and zero liquid discharge capabilities! 🌊✅

❓ ETP FAQs: Your Effluent Treatment Plant Questions Answered

🤔 What is an Effluent Treatment Plant (ETP)?

An Effluent Treatment Plant (ETP) is a specialized industrial wastewater treatment facility designed to treat effluent discharge from manufacturing and industrial processes. ETPs remove harmful chemicals, heavy metals, toxic substances, and various pollutants from industrial wastewater before releasing it to the environment or recycling it safely within your facility. Our effluent treatment plants transform contaminated industrial discharge into clean, safe water that meets all regulatory requirements. 🏭💧

🔄 How is an ETP different from an STP?

The fundamental difference lies in the wastewater source and composition:

-

ETPs (Effluent Treatment Plants) treat industrial effluents containing toxic chemicals, heavy metals, oils, and industry-specific contaminants from manufacturing processes

-

STPs (Sewage Treatment Plants) treat domestic sewage from households, residential complexes, or commercial buildings containing organic waste and biological matter

Industrial effluent treatment plants require specialized treatment processes to handle chemical complexity, whereas sewage treatment focuses primarily on biological processing. Our ETP solutions are specifically engineered for the demanding requirements of industrial wastewater. ⚗️🏢

🏭 What industries require ETPs?

Effluent treatment plants are essential infrastructure for numerous industrial sectors that generate process wastewater:

-

Textile Industry ETPs: Treating dye-laden, color-contaminated wastewater

-

Pharmaceutical ETPs: Managing chemical-intensive, drug manufacturing effluent

-

Chemical Industry ETPs: Processing highly toxic, multi-pollutant discharge

-

Dairy & Food Processing ETPs: Treating high BOD, organic-rich wastewater

-

Automotive Industry ETPs: Removing oils, greases, and metal contaminants

-

Laundry & Hospitality ETPs: Managing detergent and surfactant-laden water

-

Hospital ETPs: Treating medical, pharmaceutical, and pathological waste

-

Manufacturing ETPs: Handling diverse industrial process wastewater

Installing a compliant effluent treatment plant ensures your facility meets environmental discharge norms while demonstrating corporate environmental responsibility. 🌍✅

💧 Do you offer zero-liquid discharge (ZLD) systems?

Yes! We provide cutting-edge ZLD effluent treatment plant systems that represent the pinnacle of sustainable industrial water management. Our ZLD ETP solutions recover maximum water for reuse, minimize solid waste generation, and ensure absolutely zero liquid discharge to the environment. 🚫💧

Zero liquid discharge ETPs comply with the most stringent environmental standards, making them ideal for water-stressed regions, eco-sensitive zones, or industries committed to maximum sustainability. Our ZLD effluent treatment plants incorporate advanced evaporation, crystallization, and recovery technologies for complete water conservation. ♻️🏆

🎯 Can ETPs be customized for specific industries?

Absolutely! Customization is fundamental to effective effluent treatment plant design. Our ETP solutions are meticulously tailored to address:

-

Specific pollutants and contaminants in your industrial discharge

-

Actual wastewater flow rates and volume fluctuations

-

Unique industry processes and operational patterns

-

Regulatory compliance requirements (CPCB/SPCB norms)

-

Space constraints and site conditions

-

Budget considerations and operational costs

Every customized ETP we design ensures optimal compliance, treatment efficiency, and cost-effectiveness for your unique industrial requirements. Our effluent treatment plant engineers analyze your wastewater characteristics thoroughly before recommending the perfect technology combination. 🔬🛠️

🔧 What are the main components of an ETP?

A comprehensive effluent treatment plant integrates multiple specialized components working synergistically:

-

Equalization Tanks: Buffer flow and concentration variations in industrial effluent

-

Chemical Dosing Systems: Precisely add treatment chemicals for coagulation/flocculation

-

Clarifiers: Separate settled solids from treated water in the ETP

-

Aeration Tanks: Provide biological treatment through controlled oxygen supply

-

Filtration Systems: Remove fine suspended particles from ETP effluent

-

Sludge Dewatering Units: Process and concentrate solid waste from the effluent treatment plant

-

Disinfection Systems: Final pathogen elimination before discharge or reuse

Each component in our ETP designs is carefully sized and integrated to ensure optimal industrial wastewater treatment performance. 🏗️⚙️

📊 What pollution parameters does your ETP reduce?

Our effluent treatment plants effectively reduce all critical industrial wastewater pollutants:

-

BOD (Biological Oxygen Demand): Organic matter requiring oxygen for decomposition

-

COD (Chemical Oxygen Demand): Total organic pollutant load in ETP influent

-

TSS (Total Suspended Solids): Suspended particulate matter concentration

-

TDS (Total Dissolved Solids): Dissolved inorganic and organic substances

-

Heavy Metals: Lead, chromium, mercury, cadmium, arsenic removal in ETPs

-

Oils & Greases: Hydrocarbon and lipid contaminants in industrial effluent

-

pH Imbalance: Neutralization of acidic or alkaline wastewater

-

Industry-Specific Pollutants: Specialized contaminants unique to your process

Our ETP systems consistently achieve discharge parameters well within regulatory norms, ensuring environmental compliance and legal safety. 📉✅

📜 Are your ETPs compliant with CPCB/SPCB norms?

Yes, absolutely! All our effluent treatment plant designs meet or exceed standards established by:

-

CPCB (Central Pollution Control Board) national guidelines

-

SPCB (State Pollution Control Board) regional requirements

-

Industry-specific discharge norms and consent conditions

Our ETP compliance ensures complete legal conformity, eco-friendliness, and protection from regulatory penalties. We design every effluent treatment plant with regulatory compliance as a fundamental requirement, not an afterthought. Each ETP we deliver includes performance guarantees for specified discharge parameters. 🏛️🌿

🔧 How often does an ETP need servicing or chemical replenishment?

Effluent treatment plant maintenance requirements vary based on wastewater characteristics and treatment intensity:

-

Daily Checks: Basic operational monitoring of ETP equipment and parameters

-

Weekly/Monthly: Chemical replenishment for coagulation, pH adjustment, disinfection

-

Quarterly Servicing: Professional comprehensive inspection and maintenance of effluent treatment plant systems

-

Annual Overhaul: Major equipment servicing, calibration, and performance optimization

Consistent ETP maintenance ensures optimal industrial wastewater treatment performance, extends equipment lifespan, and prevents costly emergency repairs. Our effluent treatment plant service contracts provide hassle-free maintenance management. 🛠️📅

📱 Can you automate ETPs and provide remote monitoring?

Yes! We offer advanced automated ETP systems featuring cutting-edge control technologies:

-

Full ETP Automation: Eliminate manual operations through intelligent process control

-

Remote Diagnostics: Monitor your effluent treatment plant from anywhere globally

-

Cloud Data Logging: Continuous performance tracking and historical analysis

-

Instant Alerts: Receive notifications for ETP parameter deviations or equipment issues

-

Mobile App Control: Manage your effluent treatment plant operations via smartphone

-

AI Optimization: Machine learning algorithms optimize ETP chemical dosing and energy use